Products & Services

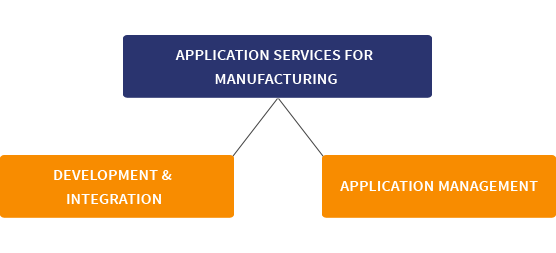

Our Application services for your company are customized to cater to your unique requirements. We understand that the manufacturing industry is driven in water-tight compartments that focus on strict deliverables. The pursuit to sustain effective and scalable operations requires a comprehensive application that would effectively integrate and control your manufacturing systems and processes to optimize resource and capacity. Our application services include DEVELOPMENT & INTEGRATION of applications and their complete MANAGEMENT.

Quadruple Automation offers staffing solutions on specific IT skill sets. You can turn to us for all your contingent IT skill resource needs at anytime and we will give you the best of talent. Our solutions are flexible and we ensure that the resource perfectly fits the skill and job-role requirement. We have a skilled talent pool with expert and in-depth knowledge in their respective domains and understand your work style and organization culture.

Rely on us for your staffing requirements and you:

- Will not have to worry when resources leave at a critical time.

- Alleviate pressure during ramp up or during a ramp down on projects.

- Are Relieved of training or induction exercises.

- Benefit from Cost effectiveness and reduction on time and cost in your payroll.

Quadruple Automation Services provides holistic IT solutions to manufacturing companies which are designed to increase the productivity of resources and gives you a high return on investment. We develop IT solutions that drive efficiency across the various systems and processes in any manufacturing unit and facilitate management personnel to manage people and processes effectively.

Our experience in developing and delivering IT solutions for top-notch manufacturing companies has shaped the thought process of our expert team enabling them to create and design solutions that best serve the needs of the manufacturing unit. We have successfully developed and deployed key manufacturing projects and we offer custom IT solutions in various segments:

Our team has experience in:

- Industrial control systems engineering

- Process control technology

- Production Scheduling

- Real Time Process Information Management

- Process Management / Steady-state Simulation

- Production Management and Execution

- Manufacturing Visibility and Intelligence

- Performance Analysis and Reporting

- MES integration with Plant Control Systems, ERP, SCM, and PLM

- Device Net product development, manufacture and installation

- Neural Technology (DH+, Device Net, Control Net, Ethernet, Remote I/O, Modbus, RS422)

- SCADA / HMI development and implementation (Smart Controls Reviews, In touch, Fix, Panel view, Interact etc.)

Custom Solutions

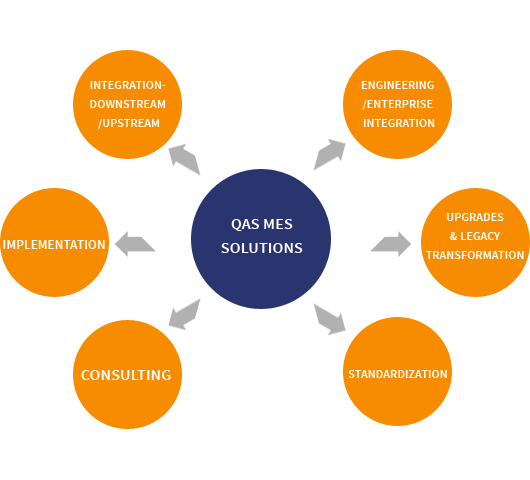

Quadruple Automation works on MES that creates the essential connect between the shop floor, control and coordination systems, and your ERP. This would enable greater synchronization and well coordinated information links for better control on productivity and quality.

Designing and Developing a MES requires a complete research on the type and detail of the manufacturing process and 'CUSTOMIZE TO SCALE HIGHER' is the mantra of the QAS team, when it comes to delivering a solution on MES. Rely on us for all your IT solution needs on MES.

We create MES solutions for effective and consistent operational execution with well-defined capabilities. Based on the best industry practices we build software that is capable of handling and processing operational improvements with an incremental approach. Our solutions are completely scalable and configurable with deployment risks at the lowest level. The key focus of our expert team while designing and deploying an IT solution for MES is to drive operational efficiency and lower Total Cost of Ownership.

Quadruple Automation works on MES that creates the essential connect between the shop floor, control and coordination systems, and your ERP. This would enable greater synchronization and well coordinated information links for better control on productivity and quality.

Our experience spans across a wide range of MES products and services and is represented below:

QAS with expertise in developing customized solutions for warehouse management primarily for manufacturing industries has benefited global manufacturing customers to a great extent in terms of carrying stocks of required materials within the defined permissible stock level.

Our team at QAS is capable of building customized solutions for the unique needs of your Warehouse. We design and develop according the client’s requirement and ensure that the solution is a perfect fit. We help you keep pace with market demands and ease the in and out of stock to ensure that the warehouse is always at its optimal storage capacity. You can benefit from a streamlined process, cost and inventory control and increased profits by using our Warehouse Management solutions.

Benefits

- Maintain a balance between too much and too little inventory.

- Reduce expenses on labor and storage by managing tasks and improving processes.

- Helps companies cut expenses by minimizing the amount of unnecessary parts and products in storage.

- Traceability

- Modeling and managing the logical representation of the physical storage facilities (e.g. racking, etc.).

- Access to real time reporting.

- Tracking where products are stocked, which suppliers they come from, and the length of time they are stored. By analyzing such data, companies can control inventory levels and maximize the use of warehouse space.

- Increased throughput with integration.

- Material request through transaction based.

Kitting is an important inventory and assembly management process .Kitting is an assembly function as it is the grouping of separate but related products together. Once these multiple unique parts packaged together, they are presented in the assembly line. Now Kitting is the actual picking mechanism of the right part or the right component, for those related parts that would also be picked to assemble into the final product or a part of the final product. At Quadruple Automation Services we identify areas in manufacturing that can use IT solutions to leverage and maximize productivity and efficiency and reduce errors and rework.

A well-defined and effective Kitting process is determined by the picking system used. At QAS we only use the best of the Digital Picking System to ensure the Kitting Process is one that adds value to the assembly line enabling greater inventory management and reduced overall deliveries in the assembly line.

DPS system is a paperless picking system that uses light modules to pick goods instead of using an invoice or paper to put goods in order or place them in their pre-determined or allocated space in the warehouse or the assembly line. The Pick-to-Light system widely supports the speedy and accurate distribution of goods and is a technology or procedure that has been accepted hands down by manufacturers and warehouse and inventory managers.

Benefits of the Digital Picking System

- Increases the speed of the picking process dramatically

- Reduces duplication at the time of order fulfillment

- Aligns and coordinates to facilitate a smooth kitting process

- Eliminates or reduces sequencing issues in the assembly line

- The picking system is paperless and thereby reduces the missing of details.

- Ensures that the right components are picked for the right packages or kits reducing errors and cost.

Manufacturing companies are in the constant and critical fight to keep at quality parameters and work towards Total Quality Management (TQM). At QAS we take care of your quality management needs and create solutions that streamline operational activities and give you a clear insight on the areas you need to focus – COST & QUALITY. Working efficiently to aid and make your ISO 9000 standardization process easier, our quality management solutions link to all your manufacturing related data management systems and your ERP. We have worked on Quality Management Solutions for renowned Automobile and Tyre production companies. These manufacturing companies follow rigorous quality checks at almost every level to adhere and maintain quality standards, and this experience has given our team a clear insight on all those aspects and elements that must be taken into consideration before designing a Quality Management Solution.

Benefits

- Reduces the overhead of managing ISO 9000

- Automate the tedious and time consuming tasks

- Timely root cause analysis

- Security and System Integrity

- Visibility of quality parameters of every product

- Defect data collection

- Corrective action data

- Test data collection

- Quality stops

Automating pricing lists we ensure that the user interface remains uncompromised while showcasing and featuring their entire product range and the various permutations and combinations of product varieties the customer can juxtapose choosing a unique product combo or a combo of products to suit their specific requirements.

Our expert team is adept in understanding the unique Price List Automation needs of every product as they take into account the type, target segment, reach and utility of the product before arriving at a flexible design. You can depend on us to deliver the best solution for your Price List Automation needs.

Benefits

- Displaying the pricing and price of the products in multiple currencies

- Built – in capacity to handle 50000 different products

- Media Access Control Protection for the addresses of customers

- Store, manage and generate data and reports on vendors and information pertaining to them.

- Admin has the facility to create and control multi-level access for the different type of users who access the software for information and process.

No: 6/26

1st Floor

Palayakkaran Cross Street

Kodambakkam

Chennai-600024.